Customer Success Journey

There is a saying “Customer is always right and they teach you everything about the business” This has been true in case of VCB. It has been a tremendously enriching journey for the leaders and workfolks of the VCB Electronics as articulated in the adjacent timeline of last two decades.

Winning the first business for any electronics manufacturing start up is a glorious moment. Vikram Sarabhai Space Center, Thiruvananthapuram was the first customer to train, qualify and entrust work to VCB Electronics, GIC was the first Industrial customer to follow VSSC. Thus began the exciting journey into space and industrial electronics manufacturing.

The milestones we have achieved in this journey signifies, the hard work towards and sincere dedication to design and make in India. Quality mindset, precise process, system, infrastructure, technology know how and deep customer relationships have been foundations and pillars of VCB Electronics.

We have have been improving and exceling over the years and proud to be able to offer first time right and zero defect products to our key customers.

We strongly believe that our customer success is our success. Hence win-win situation for both.

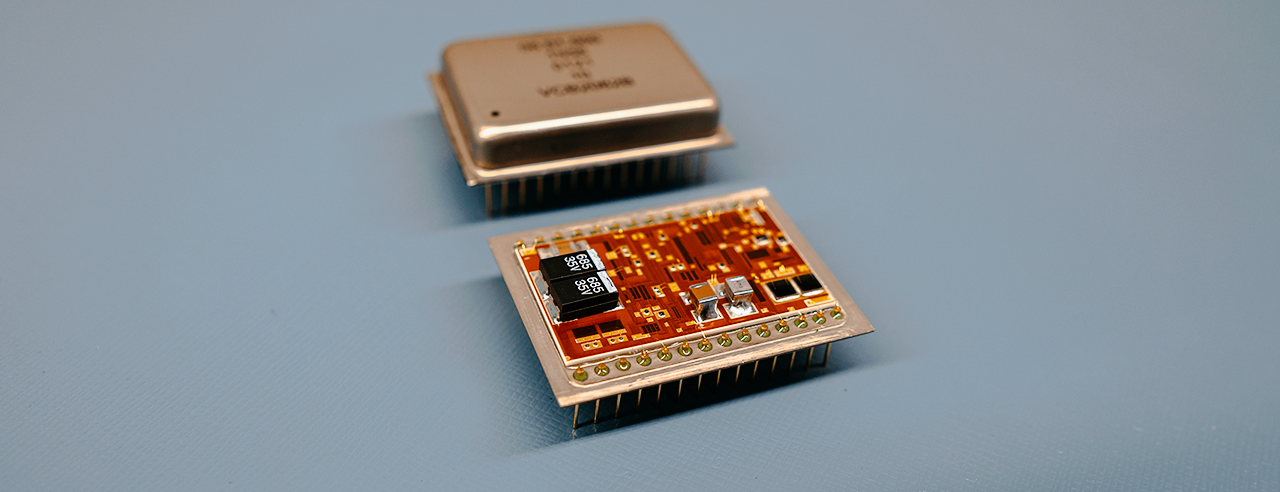

Success Story on Hybrid Micro Circuits

Hybrid Micro Circuits offer distinct advantages like lower weight, smaller size, higher reliability and better performance in a mission critical application like satellite and launch vehicles. ISRO qualification includes Infrastructure, equipment, process, people, practices and VCB has progressively gained all necessary qualifications as a manufacturing partner. HMCs manufactured by VCBs conform to MIL 883 standards as stipulated by ISRO.

VCB Electronics was initially trained and qualified to assemble printed circuit boards for launch vehicles. VCB started supplying the PCB assemblies and screened components to Vikram Sarabhai Space Center (VSSC) in 2002, followed by component screening services in 2006.

VCB Electronics received qualification for payload PCB assemblies in 2006 and for hybrid micro circuits from Space Application Center (SAC) in 2011 and UR Rao Satellite Center (URSC) in 2013. Since then VCB has supplied numerous HMCs that have been part of satellite payloads and space missions executed by ISRO.

VCB Electronics received qualification in 2015 for its own designed, engineered and manufactured DC-DC Converters for use in satellite, launch vehicle and ground applications. In 2020 VCB got qualification to manufacture and supply SAW Filters for payload applications as well.

“VCB has achieved zero rework in space grade hybrid microcircuits processes and delivered product on time “ says an Indenter at URSC, Bengaluru in Feb 2020. This trust shown by the customer is the biggest reward for us.

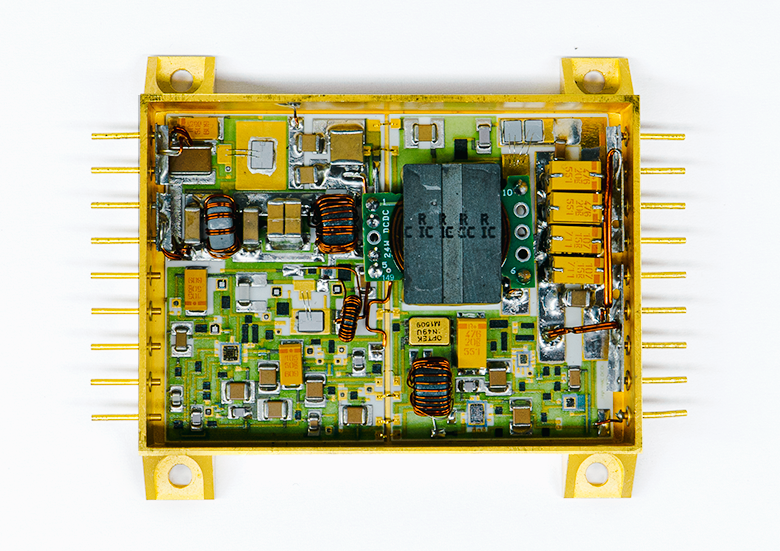

Success Story on DC-DC Converter

VCB Electronics is a competent, qualified, certified, mission critical manufacturing partner for Indian Space Research Organization. Over the years, VCB has taken more ownership and responsibility to source, screen, qualify, design hybrid micro circuits as per needs of their customer, thus adding immense value to the customer.

VCB Electronics has developed smallest space grade DC-DC converter in the world based on thick film hybrid technology through innovative mind in assistance with ISRO -- says Director at IISU Thiruvananthapuram. A DC-to-DC converter is an electronic circuit or electromechanical device that converts a source of direct current (DC) from one voltage level to another. It is a type of electric power converter.

VCB is the only private company in India that has capability and competence to design, develop, manufacture varieties of high performance, high efficiency, high reliability DC-DC Converters for satellite pay loads, launch vehicle and ground applications. VCB has combined complex processes like, multi layered thick film printing, chip and wire bonding, ferrites and wire wound component mounting and advanced soldering and epoxy based attachment techniques on ceramic substrate. VCB has inhouse developed design techniques like efficiency improvement, thermal management using high frequency switching and package design. VCB has used pre-screened components to improve the reliability and performance of the DC-DC converters.

VCB Electronics got qualified in 2015 to supply DC-DC Converters to Vikram Sarabhai space Centre (VSSC), Space Application Center (SAC) and ISRO Inertial System Unit (IISU). In last 5+ years, VCB has supplied more than 1500 units of space grade and launch vehicle grade DC-DC Converters.

Sensor Nodes

VCB SS 210 E high-sensitivity motion sensor of security system VCB 210, types A(B). The product uses highly sensitive photodetectors, as well as the latest in-own developments, which ensures high quality.